In today’s interdependent global economy, having a clear understanding of the flow of goods, services, and information is critical to maintaining a competitive edge. Companies that master their operational processes can reduce costs, improve customer satisfaction, and increase overall efficiency. Two foundational concepts in this ecosystem are logistics and the supply chain. While often used interchangeably, these terms refer to distinct but deeply interconnected aspects of moving goods and managing resources.

TL;DR

Logistics is a component of the broader supply chain, focused on the movement and storage of goods. The supply chain encompasses the entire process – from sourcing raw materials to delivering the final product to the consumer. Logistics operates within supply chain management but cannot exist effectively in isolation. Understanding the difference between the two can lead to better decision-making and improved operational efficiency.

Defining Logistics

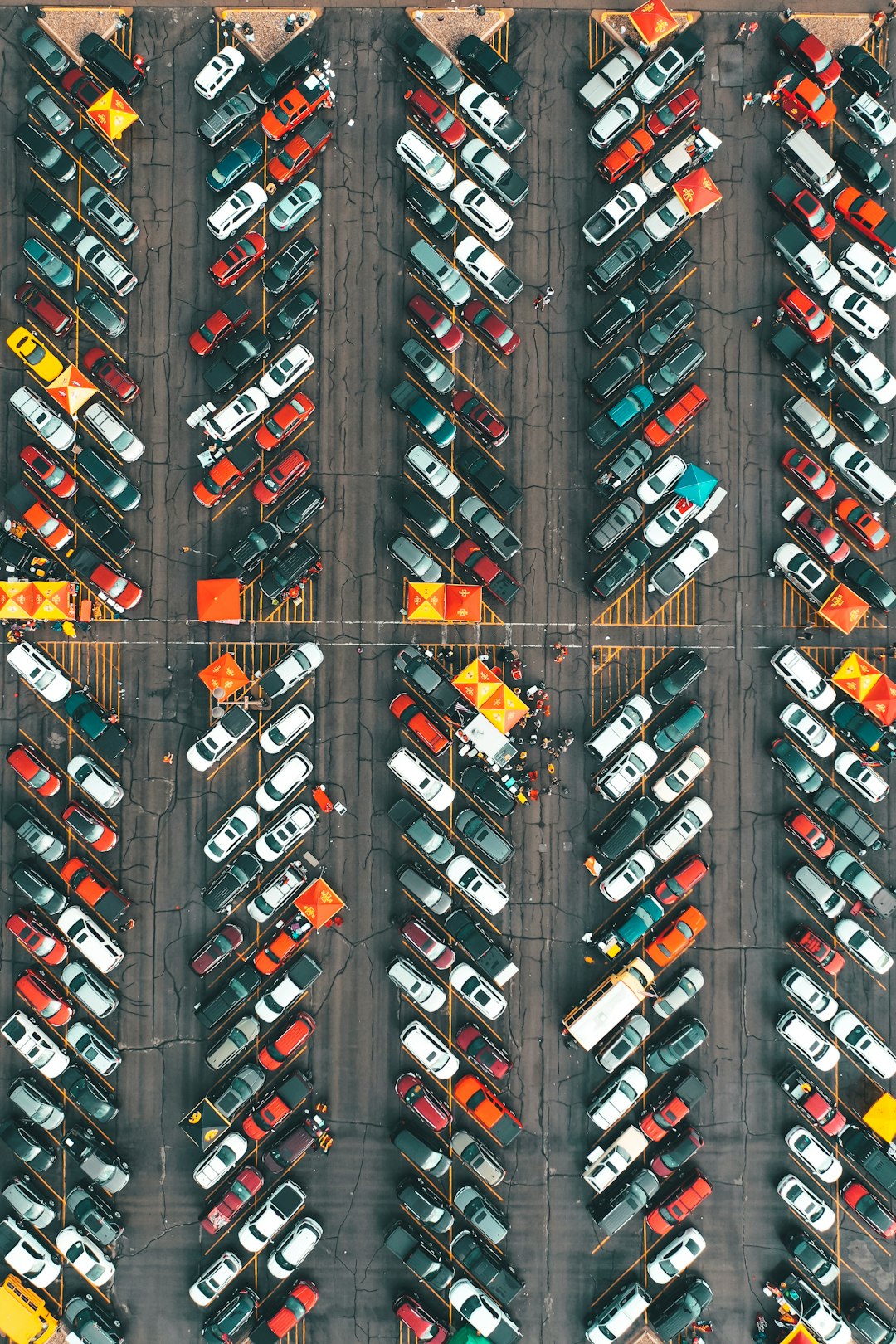

Logistics refers to the tactical processes involved in the transportation, warehousing, and distribution of goods. It includes functions like:

- Inbound transportation (receiving goods)

- Warehousing and inventory management

- Outbound transportation (shipping goods)

- Order fulfillment

- Fleet management

The purpose of logistics is to ensure that the right product reaches the right location at the right time, in the right condition, and at the lowest possible cost. It is a subset of supply chain management (SCM), responsible for the flow of goods from one point to another.

Understanding Supply Chain

The supply chain encompasses a broader and more strategic perspective. It includes not only the logistical aspects but also the coordination and management of suppliers, manufacturers, distributors, and retailers. The components of supply chain management typically involve:

- Supplier relationship management

- Procurement of raw materials

- Production planning and execution

- Inventory strategy

- Logistics and distribution

- Customer relationship management

- Data analytics and performance measurement

In simple terms, while logistics is concerned with managing product flow, supply chain management deals with managing the entire lifecycle of a product.

Key Differences Between Logistics and Supply Chain

Although logistics is a key function within supply chain management, the two are differentiated by their scope, focus, and objectives:

1. Scope

Logistics focuses mainly on the movement and storage of goods, both internally within a company and externally between businesses and consumers.

Supply Chain Management has a broader scope—it involves not only the internal logistics but also external processes like procurement, coordination with suppliers, and customer service.

2. Strategy vs. Operation

Logistics is more operational in nature. It is concerned with the daily activities that ensure goods get from point A to point B effectively.

Supply Chain is more strategic. It looks at long-term trends, strategic partnerships, and the optimization of the entire business process from raw material to consumer.

3. End Goal

The main goal of logistics is to ensure timely and cost-effective delivery of goods.

The supply chain’s end goal is to create a competitive advantage by delivering maximum value to customers through coordinated efforts across functions.

4. Data and Communication

Logistics typically deals with tangible data—shipment schedules, warehouse volume, delivery routes.

Supply Chain Management incorporates both tangible and intangible dimensions, such as supplier trust, brand impacts of delivery times, and sustainability metrics.

Integration Between Logistics and Supply Chain

Despite their differences, logistics and supply chain functions are highly interdependent. For a supply chain strategy to succeed, it must integrate effective logistical support practices. Conversely, without alignment to broader supply chain goals, logistical efforts can become disconnected, leading to inefficiencies such as:

- Overstock or stockouts

- Increased transportation costs

- Delayed deliveries

- Poor customer experiences

Modern businesses use sophisticated technologies like ERP (Enterprise Resource Planning) systems, WMS (Warehouse Management Systems), and TMS (Transportation Management Systems) to ensure this integration is seamless. Real-time data sharing among departments and supply chain partners helps ensure that logistics decisions are aligned with strategic business objectives.

Importance in Different Industries

Different industries rely on logistics and supply chain management in unique ways:

- Retail: Fast-moving goods and seasonal fluctuations make efficient logistics crucial. The supply chain must react quickly to consumer demands.

- Manufacturing: JIT (Just-in-Time) manufacturing relies on seamless procurement and logistics processes to avoid costly delays.

- Healthcare: The timely delivery of medical products and adherence to regulatory requirements put extra pressure on logistics efficiency.

- Technology: Globalized production networks require highly coordinated supply chain operations, often across several countries.

In each of these sectors, a well-functioning logistics framework is the engine that drives supply chain performance.

Technology’s Role in Logistics and Supply Chain

As digital innovation accelerates, the line between logistics and supply chain management continues to blur. Technologies such as:

- IoT (Internet of Things): Real-time tracking of shipments and assets

- AI and Machine Learning: Demand forecasting and route optimization

- Blockchain: Improved transparency and trust in complex transactions

- Robotic Automation: Smart warehouses and automated fulfillment

These innovations emphasize the need for cross-functional integration. Data-driven decision making allows organizations to be more agile, reduce risks, and improve customer satisfaction through better logistical execution.

Challenges and Future Outlook

Both logistics and supply chain management face a range of challenges, such as:

- Geopolitical instability affecting trade routes

- Rising fuel and transportation costs

- Labor shortages in distribution and transport

- Need for sustainability and reducing carbon footprint

To address these challenges, forward-looking companies are investing in:

- Resilient supply networks: Diversifying suppliers and logistics partners

- Green logistics: Electric vehicles, optimized routes, and eco-friendly packaging

- Predictive analytics: Leveraging big data to anticipate and mitigate issues

The future of logistics and supply chain lies in collaboration, technological integration, and sustainability. Companies that adapt to these evolving dynamics will be better positioned to compete in a rapidly changing marketplace.

Conclusion

In essence, logistics keeps the wheels turning day-to-day, while supply chain management steers the overall direction of the business. Though the terms are often used interchangeably, a clear distinction improves clarity in strategic planning, decision-making, and operational execution. Understanding both the differences and the synergies between logistics and supply chain is essential for any organization looking to thrive in a complex and competitive environment.